Monitoring and managing fluids plays a crucial role across various industries, from environmental management to industrial applications. The effective handling of fluids not only promotes efficiency but also enhances safety standards.

As industries evolve, innovative solutions emerge to tackle the complexities associated with fluid management. Modern technology, data analytics, and intuitive designs are transforming how organizations monitor, manage, and manipulate fluid systems.

Understanding Fluid Management Systems

Fluid management systems involve the monitoring, controlling, and optimization of fluids in various applications, such as manufacturing, irrigation, and water treatment. These systems encompass a range of technologies that provide real-time insights into fluid dynamics. Organizations strive to enhance their operational efficiency by utilizing precise monitoring tools.

Recent advancements in sensor technology allow for highly specialized and accurate readings often communicated through cloud platforms. A fluid management system typically comprises sensors, data loggers, and control interfaces. Sensors capture data related to flow rates, temperatures, and pressure levels, ensuring that managers have comprehensive insights available at their fingertips. Collecting and interpreting this data enables quick responses to potential issues, preventing accidents and inefficiencies.

Hose Floats: A Cutting-Edge Solution

Hose floats represent a revolutionary development in fluid management systems. With the capability to monitor fluid levels from various hoses, they enhance efficiency and reduce waste. The team behind EZ Connect Floats has pioneered the integration of advanced materials designed to withstand harsh conditions while delivering reliable data.

The deployment of hose floats simplifies previous manual processes that required constant attention. Instead, operators can rely on data collected from multiple hoses to manage their operations effectively.

Hose floats reduce overflow and mismanagement hazards by enabling real-time fluid tracking and status reports. These floats can be tailored for specific applications, whether in agricultural settings seeking to maintain irrigation levels or in industrial processes where precision is paramount. The ability to adapt to different operational environments enhances their utility.

Innovative Tools for Fluid Monitoring

Recent innovations in fluid monitoring technologies have reshaped industry standards. One significant advancement is the use of smart sensors that not only track fluid levels but also predict trends related to usage and potential leaks. These proactive capabilities minimize downtime and losses. Integrating these sensors with smartphone applications increases user accessibility, allowing for remote monitoring and control.

The emergence of the Internet of Things (IoT) has enhanced fluid management further. IoT-enabled devices gather real-time data and streamline communication between the equipment and operators. Users can receive feedback instantly about any irregularities in fluid levels, prompting immediate corrective measures.

Real-World Applications of Fluid Monitoring Technologies

Various industries benefit significantly from fluid monitoring innovations. In agriculture, real-time monitoring systems enable farmers to optimize water usage, directly impacting crop yield. Better monitoring directly correlates to enhanced water conservation techniques, which is crucial in our warming world. In industrial settings, accurate fluid management leads to improved efficiency.

Factories that integrate smart fluid management systems report not only reduced waste but also lower operational costs. Predictive analytics can forecast fluid depletion and maintenance needs, allowing for more efficient resource allocation.

Challenges in Fluid Management

While innovative solutions are redefining fluid management, challenges persist. One primary concern is the integration of new technologies with legacy systems. Many organizations face hurdles in upgrading their existing setups. Compatibility issues can lead to increased costs and extended timelines. Education and training for personnel are also critical. Staff must understand how to utilize new technologies effectively to maximize their benefits.

Without adequate training, there can be misinterpretations of data, leading to poor decision-making. The initial investment required for advanced fluid management systems can be a barrier for smaller organizations or those with limited budgets. Ensuring data security and privacy in IoT-enabled systems is another growing concern, as these technologies become more interconnected.

Image source: Pexels

The Future of Fluid Management

The future of fluid management is brimming with potential as new technologies continue to emerge. The incorporation of artificial intelligence into monitoring systems can further enhance prediction accuracy and automate routine tasks. This advancement could lead to a significant reduction in human error and operational disruptions.

Sustainability will likely become an even larger focus as industries look to reduce their environmental impact. Innovations that promote efficient fluid use will not only benefit organizations financially but also align with global sustainability goals.

AI-driven systems could optimize fluid usage in real time, adjusting flow rates and pressure levels based on predictive analytics. Advancements in biodegradable materials and energy-efficient pumps could further minimize the ecological footprint of fluid management processes. Collaborative efforts between industries, governments, and technology providers will be essential to drive innovation and ensure widespread adoption of these sustainable practices.

Innovative solutions for monitoring and managing fluids are revolutionizing industries by enhancing efficiency, safety, and sustainability. From advanced sensor technologies and IoT-enabled devices to cutting-edge tools like hose floats, these innovations provide real-time insights and predictive capabilities that transform how organizations handle fluid systems.

Industries such as agriculture, manufacturing, and water treatment are already reaping the benefits of these advancements, achieving improved resource management, reduced waste, and lower operational costs.

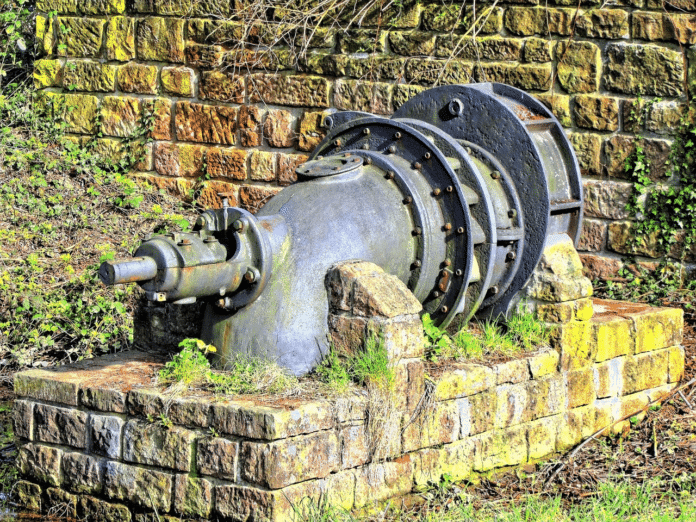

Main Image source: Pixabay